Research and development

Research and development

The core activity of the R&D team is the development of new products, components and technologies to be applied in future projects for our customers. In this area, the team works closely with the R&D group at the German headquarters. Each of the developers leads several projects, which they consult within the global team. This could be, for example, the development of a new plastic bowl or the conceptualisation of a completely new product that is not yet in THK’s portfolio.

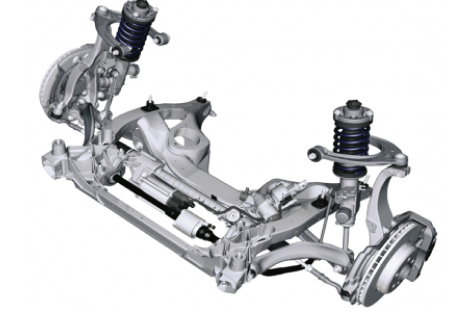

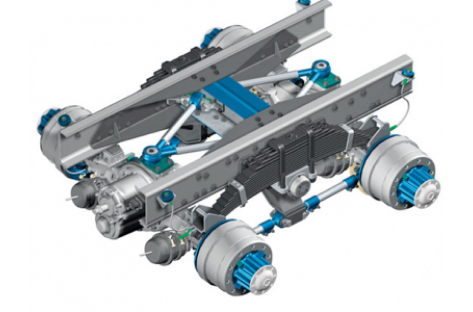

Approximately 60% of the team’s development activities are related to passenger car products, with a smaller amount of work on truck projects.

Mass production

Even in the context of series production, there are topics that need to be analysed in detail and engineering studies need to be carried out. The R&D team is actively involved in this activity. The engineers combine their experience and knowledge in the field of engineering with the technical capabilities of the development centre, especially in the field of testing and prototyping. This often leads to discovering the root causes of problems and proposing solutions.

front axle

truck rear axle

APPLICATION DEVELOPMENT

It all starts with a customer nomination. In the initial phase, members can be described as designers, as they spend most of their time fine-tuning the product design (design in 3D). Subsequently, it is mainly about the technical management of the project. Directly with the customer they mainly deal with testing and verification of the proposed design. Intensive cooperation also takes place within the company. Tests are commissioned, prototypes are produced, technical problems are solved and consulted with production, quality and technology. The highlight of the project is the start of series production

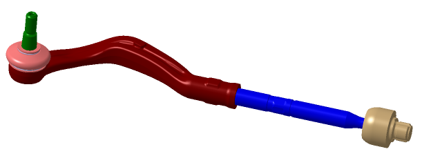

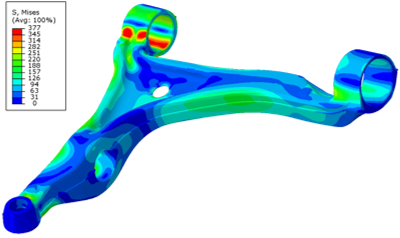

calculations

Especially in the first stages of development, finite element calculations are used. Before the first prototypes are built, the strength of the parts, their resistance to material fatigue and the simulation of damage (bending) during vehicle impact are verified.

The calculations can also be used to optimise the weight of the product while maintaining other mechanical properties.